Production

PEB Fabrication

Submerged arc Welding

Advantages

- Improved safety.

- Weld metal deposit possesses uniformity, good ductility, corrosion resistance and good impact strength.

- Molten flux provides very suitable conditions for high current to flow. Because of high heat concentration, considerably higher welding speeds can be caused.

CNC Plasma Cutting

High Quality & Accurate Cut

Plasma cutting is a process that cuts through electrically conductive materials by means of an accelerated jet of hot plasma. Typical materials cut with a plasma torch include steel, stainless steel, aluminum, brass and copper. High precision CNC plasma cutting ensures high quality cut with smooth edge surface which is most perfect for welding process. It can achieve a comparable quality level to laser cutting. Also we can cut various complex and contour shapes without difficulty.

Characteristics

Advantages

- High Quality Cut

- Smooth Edge Surfaces

- Metallurgical perfect surfaces for welding

- Excellent cutting speed

- Wide range of material

- Wide range of thickness

- One and more cutting torches

- Keeps materials cool

Space Frame

Manufacturing

Research and Development

Pipe / Member Fabrication

Corrosion and Fire Protection

Ball / Node Manufacturing

Roofing and Cladding Sheets

One of our major challenges was the redesign of our roofing and cladding sheets, which took nearly a year of intensive research and development. After multiple refinements, we successfully developed roofing sheets with an additional rib on the crest to improve load-bearing capacity while ensuring an appealing design. Our cladding sheets features a reverse profile, giving it the sleek look of a false ceiling for a seamless aesthetic.

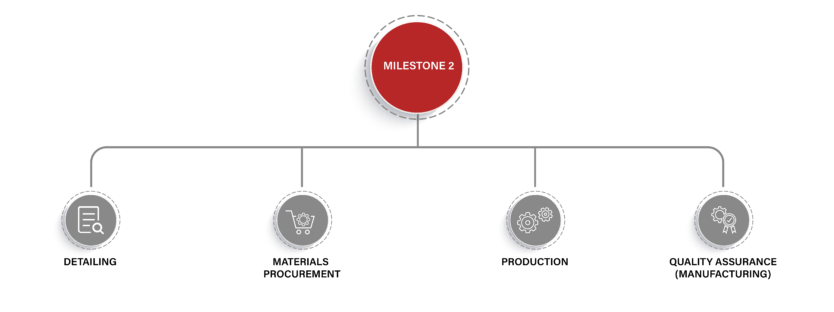

- Production

- Design & Detailing

- ERP

- Safety Standards

PEB Fabrication

Submerged arc Welding

Advantages

- Improved safety.

- Weld metal deposit possesses uniformity, good ductility, corrosion resistance and good impact strength.

- Molten flux provides very suitable conditions for high current to flow. Because of high heat concentration, considerably higher welding speeds can be caused.

CNC Plasma Cutting

High Quality & Accurate Cut

Plasma cutting is a process that cuts through electrically conductive materials by means of an accelerated jet of hot plasma. Typical materials cut with a plasma torch include steel, stainless steel, aluminum, brass and copper. High precision CNC plasma cutting ensures high quality cut with smooth edge surface which is most perfect for welding process. It can achieve a comparable quality level to laser cutting. Also we can cut various complex and contour shapes without difficulty.

Characteristics

Advantages

- High Quality Cut

- Smooth Edge Surfaces

- Metallurgical perfect surfaces for welding

- Excellent cutting speed

- Wide range of material

- Wide range of thickness

- One and more cutting torches

- Keeps materials cool

Space Frame

Manufacturing

Research and Development

Pipe / Member Fabrication

Corrosion and Fire Protection

Ball / Node Manufacturing

Roofing and Cladding Sheets

One of our major challenges was the redesign of our roofing and cladding sheets, which took nearly a year of intensive research and development. After multiple refinements, we successfully developed roofing sheets with an additional rib on the crest to improve load-bearing capacity while ensuring an appealing design. Our cladding sheets features a reverse profile, giving it the sleek look of a false ceiling for a seamless aesthetic.

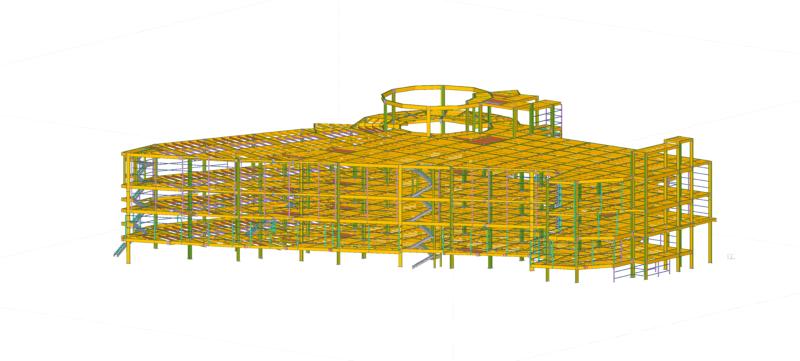

DESIGN & DETAILING

- Fabrication tolerance in accordance with IS 7215-1974 and Metal Building Manufactures Associaton (MBMA).

- Welding process, Procedure and Qualification in accordance with applicable requirments of structural welding code IS 819-1979, IS 1024-1979 and IS 1261-1959.

TEKLA DETAILING

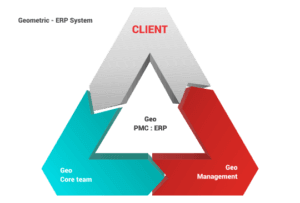

ERP

system

Safety policy

- Safety of manpower

- Safety of materials

- Environmental health

Safety of manpower

- Deploying the manpower who is fit for work.

- Providing and strictly following to wear the basic PPE’s to all without fail

- Providing the required and necessary access for each and every person who is working at heights above 2.6 Meters.

- We ensure the using of safety harness for all height works (above 2.6 meters) along with required life line systems without fail.

- We provide a good working environment (accommodation, electricity and water facility) to all site works.

- Conducting regular toolbox meetings to explain the work nature, risk assessment, and training programs.

Safety of materials

- Engaging good condition construction equipment authorized by a certified competent person.

- Using a 40% higher capacity crane for materials handling and safe erection

- Using 100% higher capacity lifting tackles for materials handling and erection.

- Carryover regular inspection for equipment, tools, and tackles

Environmental control

- Using highly maintained cranes and other equipments to avoid air and land contamination

- Providing the necessary storage area for hazardous materials like paint, thinner diesel etc...

- We have tie-up with certified disposal vendor for waste material disposal as per the government policy.

Safety Standards

- We ensure that our GSSPL Certified Building Contractors Team conducts all operations as safely and efficiently as possible.

- To abide by all safety regulations for the Central, State, Local and End-Customer.

- Develop, monitor, and enforce safety policies and practices.

- Aid the possible job site environment to prevent accidents.

- Authorize trained, experienced, and competent personnel and supervision.

- High metal deposition rates can be achieved. Single-pass welds can be made in thick plates with normal equipment.

- Assist the worker with adequate information, instruction, and training.

- Effective communication on Health and Safety matters.