Quality Team

quality policy

We at Geometrics Space Structure Pvt Ltd, are Committed to meet Customer Satisfaction through Continual improvement of Our Service and System by using Innovations, Ideas and following PDCA Technique (Plan, Do, Check, Act) in all Function and levels of our Organization.

Geometries Space Structures has acquired ISO 9001:2015, ISO 14000:2015, ISO 45000:2018 Certificate.

The proven skills with the assurance of reliability been showcased our Commitment towards Quality System Management. We practice and focus on ‘Micro Detailing’ and ‘Zero Error’ installation. Every project completed by Geometrics is Unique in its own criterion.

Inspect at every stages as auto industry

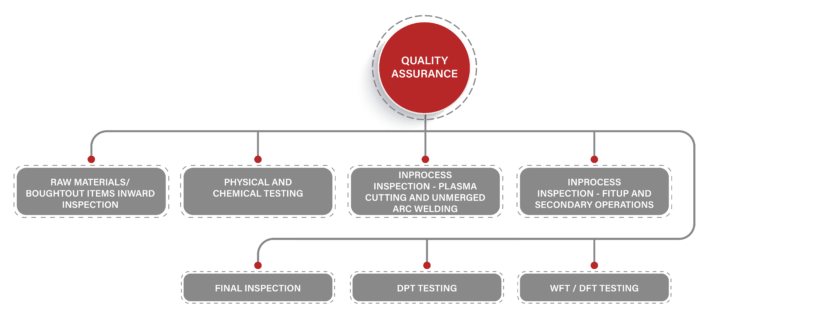

Quality assurance team will undertake quality control checks at each stage of manufacturing process to ensure the quality of our pre-engineered buildings.

MATERIALS INWARD INSPECTION

- Materials supported with Mill Test Certificate

- Raw Materials Inward Inspection & Q A Approval

- Random Physical testing

PRODUCTION IN-PROCESS INSPECTION

- Stage wise/Process wise inspection at regular interval

- Inspection is carried with competent Qualified Inspectors

- Instruments are calibrated with NABL Accredited Lab

STRUCTURAL FINAL INSPECTION

- 100% Final Inspection

- Part Numbers Punching which enables smooth Erection

TESTING

- WPS — Welding procedure Specification

- LPT — Liquid Penetrant Testing

- NDT — Non Destructive Testing

Entire manufacturing of pre engineered building parts/ assembly undergoes various strict inspection stages such as Inward Inspection, In-process Inspection and final inspection which includes destructive and non-destructive testing’s as per the Quality Plan.

Quality Objective

- Continuous Information Sharing and Training to Employees for quality Improvement and technical gradation.

- To create awareness among the team to avoid Wastage and to ensure good quality

- Continuous Improvement in Designing and Machining Area for Upgrading facilities to cater to modern Manufacturing Industries Requirements.

- To Create an excellent Working atmosphere by Maintaining good. Clean Safe Environment.

- Geometrics Space Structures has acquired ISO 9001: 2008 Certificate. This is to further assure our customers of our commitment to Quality System Management.

Quality Objective

5S Complied Company

- The 5S condition of a work area is critical to the morale of employees and the basis of customers’ first impressions. Management’s attitude regarding employees is reflected in the 5S condition of the work area.

- The 5S philosophy applies in any work area. The elements of 5S are simple to learn and important to implement:

Main Stay

Eliminate whatever is not needed

Straighten

Organize whatever remains

Shine

Clean the work area

Standardize

Schedule regular cleaning and maintenance

Sustain

Make 5S a way of life

Benefits to be derived from implementing 5S include

- Improved safety.

- Higher equipment availability.

- Lower defect rates.

- Increased production agility and flexibility.

- Reduced costs.

- Improved employee morale.

- Better asset utilization.

- Enhanced enterprise image to customers, suppliers, employees, and management.

Interested? Let’s get in touch!

If you have any questions or need more clarifications,

please do not hesitate to contact us