production

- PRODUCTION

- DESIGN & DETAILING

- ERP

- SAFETY STANDARDS

PEB Fabrication

Submerged arc Welding

Submerged arc welding is most widely used method for welding thick section in down hand position being a highly economical method for fabrication. As products must meet the more stringent requirements of quality, requiring more flexible processes to reduce cost. Quality control aspects are also becoming more important to meet regulation and monitoring and control of welding processes.

Advantages

- Improved safety.

- Weld metal deposit possesses uniformity, good ductility, corrosion resistance and good impact strength.

- Molten flux provides very suitable conditions for high current to flow. Because of high heat concentration, considerably higher welding speeds can be caused.

CNC Plasma Cutting

Plate thickness: Up to 20 mm

- High Quality Cut

- Smooth Edge Surfaces

- Metallurgical perfect surfaces for welding

- Excellent cutting speed

- Wide range of material

- Wide range of thickness

- One and more cutting torches

- Keeps materials cool

Space Frame Manufacturing

The Cone and Collar assembly is welded to Pipe / Member through MIG Welding Process. The Weld Quality is checked using Magnetic Partial Inspection.

Recommended Coating Systems:

a. Primer Coating – Epoxy / Zinc Phosphate / Zinc Chromate.

b. Epoxy Coating – for Seashore Areas where Corrosion is High.

c. Enamel Coating – 150 to 300 Microns, Based on Clients Requirement. (Most commonly used Coating System due to its ready Availability And flexibility in Repainting)

d. Fire Protection – Optional – As recommended by the Client. ( Brand : Akzo nobel International)

Spherical Nodes(Solid Balls) are manufactured using VMC Machines. Special holding devices were developed for CNC machining, Hole making and Thread forming.Holes are drilled with as much as 8 to 16 holes in various axes,. The Machining Size of the ball varies from dia 33 to dia 200. The Overall tolerance limit is +or- 50 microns in all the Operations of Ball making.

DESIGN & DETAILING

STAAD Pro Stands For Structural Analysis And Designing Program. It is Faster Method of Designing the Structure and it does not involve any Manual calculation. The Buildings shall be designed in accordance with the specification of Indian Standards

- i. Fabrication tolerance in accordance with IS 7215-1974 and Metal Building Manufactures Associaton (MBMA).

- ii. Welding process, Procedure and Qualification in accordance with applicable requirments of structural welding code IS 819-1979, IS 1024-1979 and IS 1261-1959.

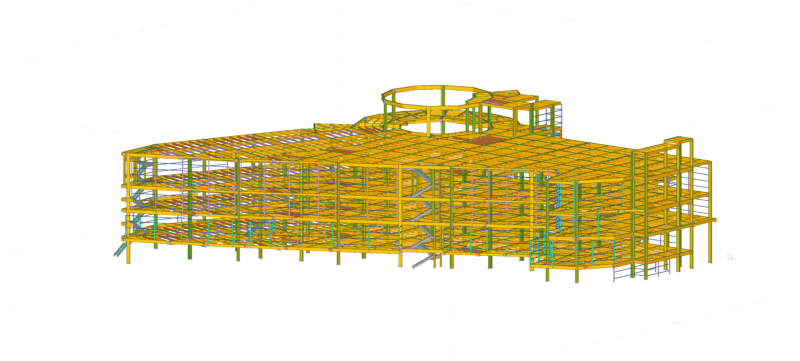

TEKLA DETAILING

Tekla Structures is powerful and flexible software for structural steel Detailing. We can create a detailed, constructible 3D model of any steel structure from industrial and commercial buildings to stadiums and high rise buildings. Working with Tekla software is the most productive way to manage detailing and realize the benefits of the model in fabrication and erection. This gives you support for delivering your projects error free and on time.

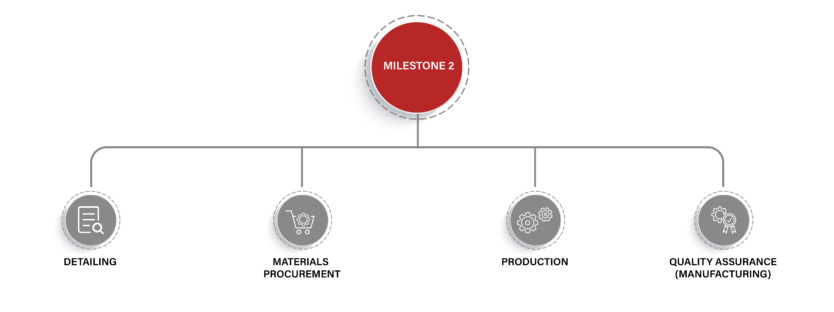

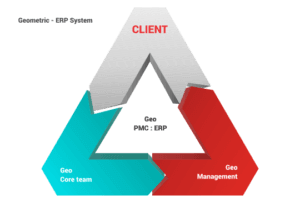

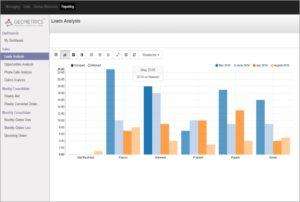

ERP

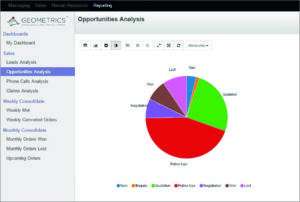

Our ERP system was developed over a period of 3 years. Working with the industry best international business consultants, Our ERP system aims mainly in fulfilling the commitments to customers. A completion schedule is derived once the project is finalized. Based on the time chart, each departments is given a specific time frame. This time frame is further managed by signals (green, orange, red and grey colour). Every step of the project is promptly informed to the client. One ERP system makes sure that our project management departments will inform the project updates to our client before they call up.

SAFETY POLICY

- Safety of manpower

- Safety of materials

- Environmental health

Safety of manpower

- Deploying the manpower who is fit for work.

- Providing and strictly following to wear the basic PPE’s to all without fail

- Providing the required and necessary access for each and every person who is working at heights above 2.6 Meters.

- We ensure the using of safety harness for all height works (above 2.6 meters) along with required life line systems without fail.

- We ensure the use of safety harness for all height works (above 2.6 meters) along with required lifeline systems without fail.

- We provide a good working environment (accommodation, electricity and water facility) to all site works.

- Conducting regular toolbox meetings to explain the work nature, risk assessment, and training programs.

Safety of materials

- Engaging good condition construction equipment authorized by a certified competent person.

- Using a 40% higher capacity crane for materials handling and safe erection

- Using 100% higher capacity lifting tackles for materials handling and erection.

- Carryover regular inspection for equipment, tools, and tackles

Environmental control

- Using highly maintained cranes and other equipments to avoid air and land contamination

- Providing the necessary storage area for hazardous materials like paint, thinner diesel etc...

- We have tie-up with certified disposal vendor for waste material disposal as per the government policy.

Safety Standards

- We ensure that our GSSPL Certified Building Contractors Team conducts all operations as safely and efficiently as possible.

- To abide by all safety regulations for the Central, State, Local and End-Customer.

- Develop, monitor, and enforce safety policies and practices.

- Aid the possible job site environment to prevent accidents.

- Authorize trained, experienced, and competent personnel and supervision.

- High metal deposition rates can be achieved. Single-pass welds can be made in thick plates with normal equipment.

- Assist the worker with adequate information, instruction, and training.

- Effective communication on Health and Safety matters.

The training provides safety awareness,knowledge that employees are required to have before entering the construction site. It provides a basic understanding of operations, and focuses on all safety aspects that a new hire needs to consider. It helps to acquire the necessary safety awareness in site.

The training provides safety awareness,knowledge that employees are required to have before entering the construction site. It provides a basic understanding of operations, and focuses on all safety aspects that a new hire needs to consider. It helps to acquire the necessary safety awareness in site.